The Science of Lithium-Ion Batteries: How Portable Power Works

Explore how lithium-ion batteries work, including the movement of lithium ions between the anode and cathode, the roles of the electrolyte and separator, different chemistries and cell designs, performance factors, safety considerations, and future directions in energy storage.

The rise of portable power

From smartphones and laptops to electric vehicles and grid‑scale storage, rechargeable batteries have become integral to modern life. At the heart of most of these applications is the lithium‑ion battery, a technology that balances high energy density, long cycle life and light weight. Understanding how lithium‑ion batteries work reveals why they have revolutionised portable electronics and transportation, and why they continue to be an active field of research.

Basic structure of a lithium‑ion cell

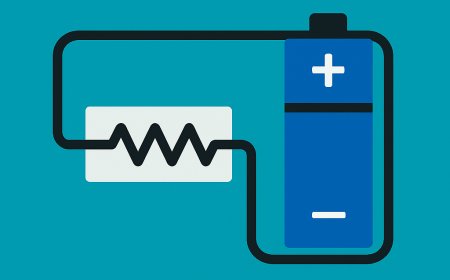

A lithium‑ion battery cell is a self‑contained electrochemical system. Inside the cell are two electrodes: the anode (negative during discharge) and the cathode (positive during discharge). The anode is typically made of porous graphite that can host lithium ions between its layers, while the cathode consists of a lithium‑containing metal oxide such as lithium cobalt oxide (LiCoO₂), lithium nickel manganese cobalt oxide (NMC) or lithium iron phosphate (LiFePO₄). Separating the electrodes is a thin microporous separator soaked with an organic liquid electrolyte containing a lithium salt. The electrolyte permits lithium ions to move between electrodes but prevents the electrodes from contacting each other and causing a short circuit.

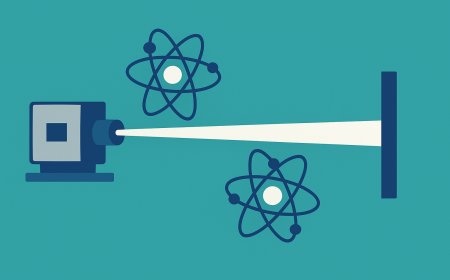

How lithium‑ion batteries work

During discharge, when the battery powers a device, lithium ions leave the anode and travel through the electrolyte to the cathode. At the same time, electrons flow through the external circuit from the anode to the cathode, performing useful work along the way. The overall reaction releases energy because lithium has a strong tendency to give up electrons and become a positively charged ion. When the battery is charged, an external energy source such as a charger forces electrons back into the anode, causing lithium ions to migrate from the cathode back into the anode. This intercalation and de‑intercalation of lithium ions—sometimes called “rocking chair” motion—is reversible, allowing the battery to be cycled hundreds or thousands of times.

Cell designs and chemistries

Lithium‑ion cells come in several formats: cylindrical cells (common in power tools and some electric vehicles), prismatic cells (used in smartphones and laptops) and pouch cells (which can be lightweight and flexible). The choice of cathode chemistry affects energy density, power output, safety and cost. Cobalt‑rich chemistries like LiCoO₂ offer high energy density but can be expensive and prone to thermal runaway if misused. Blended cathodes containing nickel, manganese and cobalt (NMC) balance energy, power and safety, while lithium iron phosphate (LFP) provides excellent thermal stability and long cycle life at a modest energy density. Emerging chemistries such as lithium nickel cobalt aluminium oxide (NCA) and high‑nickel NMC are used in electric vehicles because they support high capacity and power.

Performance and safety considerations

The performance of a lithium‑ion battery depends on several factors: energy density (how much energy can be stored per unit mass), power capability (how quickly energy can be delivered), cycle life, and operating temperature range. Lithium‑ion cells have a high energy density compared with nickel‑cadmium or nickel–metal hydride batteries and a relatively low self‑discharge rate. However, they require protective circuitry to prevent overcharging or deep discharge, both of which can degrade the electrodes and the electrolyte. To manage these risks, battery packs include battery management systems (BMS) that monitor voltage, temperature and state of charge, balancing cells and disconnecting the pack if necessary.

Thermal runaway is a safety concern: if a cell overheats due to internal shorting, mechanical damage or overcharging, it can release flammable electrolyte gases and ignite. Designers mitigate this risk with robust separators, current interrupt devices and venting mechanisms. Chemistries such as LFP are more tolerant of abuse, while cobalt‑rich cells require more careful management.

Applications across scales

Lithium‑ion batteries first became popular in consumer electronics because they allowed devices to run longer between charges without a significant increase in size or weight. The same characteristics now make them attractive for electric vehicles, where high energy density and power are essential for driving range and acceleration. In EV battery packs, hundreds or thousands of cells are combined into modules and packs, along with cooling systems and BMS. Grid‑scale storage applications use large lithium‑ion battery systems to help balance fluctuations in renewable energy generation and improve grid stability.

Limitations and challenges

Despite their advantages, lithium‑ion batteries are not perfect. The raw materials for some chemistries—particularly cobalt—can be expensive and subject to supply chain and ethical concerns. Batteries degrade over time as repeated cycling causes structural changes in the electrodes and the formation of a solid electrolyte interphase on the anode, which consumes electrolyte and lithium. Cold temperatures reduce a battery’s power output, while high temperatures accelerate degradation. Recycling lithium‑ion batteries to recover valuable materials is a growing industry but remains complex and energy intensive.

Future directions

Researchers are exploring ways to improve lithium‑ion technology and to develop alternatives. Solid‑state batteries replace the liquid electrolyte with a solid electrolyte, which could improve safety and enable the use of lithium metal anodes for higher energy density. Lithium–sulphur and lithium–air batteries promise even greater energy storage if their challenges—such as polysulphide shuttling and oxygen reactivity—can be overcome. Meanwhile, sodium‑ion batteries offer a lower‑cost chemistry that could be suitable for stationary storage. Advances in materials science, such as high‑nickel cathodes, silicon‑based anodes and improved electrolytes, continue to extend the performance and lifespan of lithium‑ion cells.

Lithium‑ion batteries have transformed modern technology by providing lightweight, rechargeable energy storage. They operate by moving lithium ions between a carbon anode and a metal‑oxide cathode through an electrolyte, with electrons flowing through an external circuit to power our devices. Different cell designs and chemistries allow engineers to tailor the trade‑offs between energy density, power, safety and cost for applications ranging from earbuds to automobiles and power grids. Understanding how lithium‑ion batteries work highlights both their remarkable capabilities and the challenges that remain in making energy storage more sustainable. Ongoing research into new materials, safer designs and alternative chemistries suggests that the future of portable and electric‑vehicle power will continue to evolve.

What's Your Reaction?